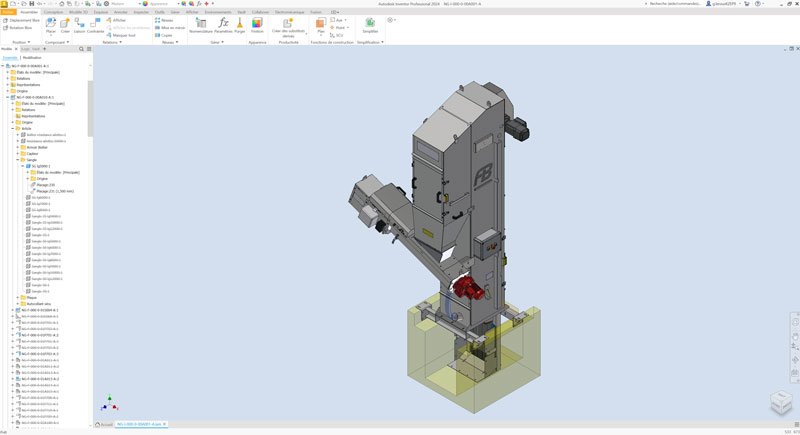

For 30 years, FB Procédés bar screens have proved their worth, and continue to win over customers with their reliability and simplicity.

This simplicity of design makes them highly adaptable, enabling them to be installed either in a channel or in a substation, and to be integrated into existing structures without any modification to civil engineering.

Our gravity principle is applied to all our bar screens, whatever their width or depth.

French 100% design and manufacture of bar screens

From the design phase to the shipment of automatic bar screens — including the “Approved for Construction” drawings sent to clients, manufacturing drawings, laser cutting, assembly, pickling/passivation, wiring, and testing — the entire manufacturing process is supervised by FB Procédés.

Choosing an FB Procédés automatic bar screen means opting for a machine that is entirely designed and manufactured in France, fully compliant with all European Conformity standards.

Gravity-operated bar screens

In a difficult environment such as wastewater treatment, machines are put to the test. Waste found in the networks (silt, wipes, sand, stones, etc.) can easily cause mechanical equipment to malfunction.

To ensure the optimal performance of its bar screens, FB Procédés developed and perfected a unique process (no other bar screen on the market uses this system): the gravity-operated bar screen.

The question behind this process is simple: how can we avoid having mechanical elements moving in the water, in order to limit the risk of blockages, but also to guarantee long-term efficiency and reliability?

FB Procédés' answer to this question was to design a mechanism based exclusively on gravity, in stark contrast to the complex hydraulic systems, chain-driven systems and switch systems frequently encountered.

The Principle:

At the start of each cycle, the screen grapple descends open and lands at the foot of the screen. Due to the effect of its own weight and a question of angle, the mobile unit changes position, the strap relaxes, and releases a sensor which activates a limit switch. The direction of rotation of the motor is then reversed, the strap is tightened, the grapple closes and engages its teeth in the grid as it rises.

The benefits:

- No submerged mechanical parts = reliability and longevity

- Gravity mechanism = maximum simplicity, much more reliable than more complex systems

- Minimum number of parts = easy, low-cost maintenance

- Technical simplicity = affordable maintenance, whatever the operator's technical level.

A central strap for traction

All FB Procédés bar screens use a single, centrally positioned belt as the traction element for the screening rake.

All our straps are made of polyester, a material that is extremely resistant to traction, tearing, ultraviolet rays, friction and humidity.

Why use straps rather than chains or cables?

Tensile strength: The breaking loads of our belts range from 3.5 tonnes to 12 tonnes. Since the screening rake rarely exceeds 500 kilograms, the breaking load of our belts is therefore at least seven times higher than the actual load.

Moisture resistance: Polyester belts withstand moisture perfectly and can remain submerged without any risk of degradation.

Low cost: Depending on the belt model, the price ranges from €10 to €15 (excl. VAT) per linear meter. We recommend replacing it once a year, or even less frequently if no signs of wear are observed. Finally, replacement takes only fifteen minutes and can be carried out without moving the bar screen structure or stopping the incoming flow.

Easy and safe replacement: Belt replacement is carried out from the bar screen installation platform. There is no need to enter the chamber or the channel, and more importantly, no need to drain them. The operation is therefore safe and can be performed by plant personnel using minimal, standard tools.

Grid and air gap

For each bar screen, the screen grid is custom-designed according to the hydraulic profile, bar spacing, and maximum flow to be treated.

Bar Spacing

It varies from 3 mm to 100 mm, depending on the application. At the design stage, the air gap is either determined by the specifications or, if not specified, by our engineering department, which will recommend the air gap best suited to the context.

Screen

Depending on the flow rate and hydraulic profile, the screen may be made of bars welded only at their lower end. We refer to this as a “free-bar” screen. This design helps prevent stones from becoming wedged between two bars and causing the bar screen to malfunction.

For larger flows and higher water heads, the bars are held in place at both ends, using a double-grid system to avoid any risk of blockage.

Material

FB Procédés bar screens are entirely manufactured from stainless steel. Depending on the specifications or requirements, optional features can be offered:

- Made entirely of 304L stainless steel

- Made entirely of 316L stainless steel

- Combined 304L stainless steel construction (above water: upper frame) and 316L stainless steel construction (below water: lower frame and screen grapple)

Servo-controlled bar screen

As standard, FB Procédés automatic bar screens are equipped with a manual control box mounted on one side of the upper frame. This box houses the connections for the limit switches and the gear motor, and features on its front panel an emergency stop push-button as well as two push buttons for “Up” and “Down” movement.

As an option, we systematically offer a control and automation electrical cabinet of our own design, equipped with a relay containing our operating program, the result of 30 years of experience.

We give our customers the choice of :

- Carry out the bar screen automation themselves, while complying with our basic electrical schematic provided upon order of the bar screen,

- Choose a "turnkey" solution with the "FB Procédés standard" control and automation electrical cabinet delivered with the bar screen.

We strongly recommend the latter solution for three main reasons:

- The bar screen will be tested and adjusted with its own electrical cabinet. In case of any issues, they will be detected during the testing and inspection phase in our workshops.

- On site, simply power the electrical cabinet, and the bar screen will then be autonomous.

- With hindsight, we're finding that we're encountering problems mainly on bar screens where we didn't supply the electrical box and our operating principles weren't respected.