EXPERTISE

FB Procedes has more than 30 years of experience in the wastewater treatment, and our range of Bar Screens is ideal for the screening of raw water, natural water, rain/storm water and industrial water. Contact UsOur expertise ? Automatic Bar Screens. According to our clients needs, we also provide our own Screw Conveyors and Screw Compactors.

Our team also has a deep knowledge and extensive experience in the design of Rotary Distributors for trickling filters.

Today, more than 5,000 of our Bar Screens are installed worldwide. More than 40 Bar Screens are made in our factory every month, and this number keeps growing.

Our experience, expertise and availability are your best guarantee to find the best Screening Systems in the industry.

DESIGN OF SCREENING SYSTEMS

All the Screening Systems we design follow the same leitmotiv: Simplicity – Reliability – Efficiency

Even though each Bar Screen is unique (screening level, width, flow, discharge height, location, etc.) and tailor-made, our entire range of Bar Screens is based on the same unique and innovative system: 2 limit sensors, 1 geared-motor, and a grapple rake hold by a single polyester strap that removes the waste from the bar screen by raking the screen at every cycle.

Over the years, our Bar Screening System has been optimised, to become one of the most reliable and efficient Bar Screening Systems in the wastewater industry.

Our Bar Screens meet the expectations of our clients: Reliable, Effficient and Easy-to-Maintain Bar Screens.

SERVICES

Our Sales Team is always available to answer your requests, and to offer you the best technical solutions according to your needs.

Wherever your project is, our Sales Managers can meet you there. Our Sales Team is always available to present you our Screening Solutions, to discuss your project, and to visit the site to take precise measures.

Based in our headquarters, a team of designers and engineers manages all your quotes requests, to offer you technical and financial proposals in the shortest time frame.

ENGINEERING

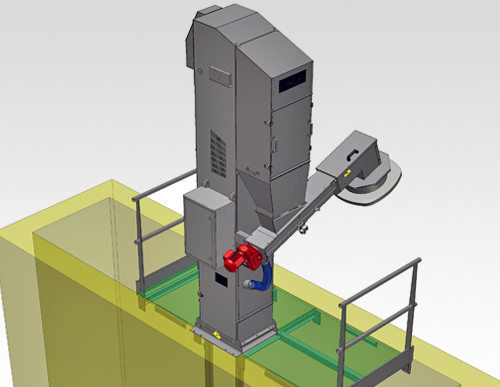

For every project our team of engineers and designers creates 3D plans of the project. Our team also constantly works on the development and opitmization of our range of Bar Screens.

Before every project is approved, we send a final plan that must be validated by the client.

Once the plan is approved, we send the plans to our factory for the production of the Bar Screen.

Manufacturing & Tests

Our entire range of Bar Screens is made in our factory, hence benefiting from the extensive experience of our technicians, as well as the advantages provided by the use of the latest manufacturing technologies (laser cutting, TIG and MAG welding, stripping and passivation, etc.).

Each Bar Screen is set and tested within a Ø2500 mm and 7000 mm deep pit, located directly inside our factory. By testing every single Bar Screen before shipping, we ensure that both mechanical and electrical components work perfectly.

This is a guarantee for our clients to have a fully functional Bar Screen upon reception.

Delivery & Installation

Before leaving our factory, our Bar Screens are wrapped with bubble pack and attached on wooden palettes.

Wherever the Bar Screen will be installed, our team of technicians can install the screen. In most cases, only one day of work is necessary to complete the installation. It’s also a good opportunity for our staff to train the local operators on how to operate the Bar Screen.

A maintenance contract can also be ordered, if you prefer to have the Bar Screen checked regularly by our technicians.